Frequently Asked Questions

Basics of Oxygen Absorber

- What is Oxygen Absorber?

- What is FreshUs Oxygen Absorbent?

- How is FreshUs different from conventional packaging methods?

- Is Oxygen really Bad?

- The Science Of Oxygen Absorbers

Applications

- Food For Long-Term Storage

- What Is Freezer Burn?

- What size Oxygen Absorbers Do You Need?

- The companies that sell long-term/emergency freeze-dried foods claim up to a 25 year shelf life. Do you think store bought food like pasta, rice, dry powdered milk, flour, potato flakes, etc can be home packaged to come close to their claim? Or what would your estimate be for home packaged food shelf life (I know it depends on the food, but you say for decades with appropriate containers)?

- Once bags are sealed and absorbers have done their job, does it make a difference what type of container these are put into for storage? Any tub, box, etc.?

- Are there better containers than vacuum-packed/sealed plastic or mylar bags?

Questions & Answers

- When packaging food items such pinto beans, where does the Oxygen Absorber go? in the bag or in the storage container/bucket

- Should you fill to the top or have space left? Frankly I don't want to make a mess of my kitchen or waste bags pouring and then saying OOPS! when things don't fit right. (I think perhaps I should have gotten some 5 gallon size bags, but thought the 1 gallon would suffice.)

- My dog ate a packet. What should I do?

Oxygen Absorbing Packets (also known as Oxygen Absorbers, oxygen scavengers, and oxygen eaters)

chemically trap available oxygen from the surrounding environment. Because oxygen is very destructive, Oxygen Absorbers

are very useful for a variety of preservation applications, especially long-term food storage and commercial food packaging.

They are also frequently used for pharmaceuticals, birdseed and pet food, medicinal herbs and artwork/artifact preservation.

Oxygen absorbers are more affordable AND more effective than vacuum-packaging and gas flushing, which are the other leading

preservation methods.

Oxygen removal preserves without chemicals or additives. They are non-toxic and categorized by the FDA as GRAS. (Generally Recognized As Safe) Oxygen absorbers are not a substitute for refrigeration or freezing and should only be used with dry, shelf-stable foods.

Oxygen Absorbers contain an iron powder formulation that becomes iron oxide in the presence of oxygen, chemically removing the oxygen from the environment at a molecular level. An oxygen absorber is like a sponge that will continue to absorb oxygen until full and needs to be kept sealed prior to use to insure it will absorb its full capacity. They come in many sizes and are rated according to how much oxygen they will absorb.

Oxygen removal preserves without chemicals or additives. They are non-toxic and categorized by the FDA as GRAS. (Generally Recognized As Safe) Oxygen absorbers are not a substitute for refrigeration or freezing and should only be used with dry, shelf-stable foods.

Oxygen Absorbers contain an iron powder formulation that becomes iron oxide in the presence of oxygen, chemically removing the oxygen from the environment at a molecular level. An oxygen absorber is like a sponge that will continue to absorb oxygen until full and needs to be kept sealed prior to use to insure it will absorb its full capacity. They come in many sizes and are rated according to how much oxygen they will absorb.

FreshUs Oxygen Absorbent is specifically designed and developed to protect packaged foods and other packaged products

agaist spoilage, mold growth, de-colorization, loss of nutritive values, insect damage, and loss of quality.

This is done by removing the residual oxygen, present inside packaged products to a level below 0.01%.

By doing this FreshUs Oxygen Absorbent is able to naturally preserve packaged foods without the use of food additives and preservatives.

FreshUs Oxygen Absorbent not only extends the shelf life of perishable food products, but helps to keep the quality of the product as well.

By doing this FreshUs Oxygen Absorbent is able to naturally preserve packaged foods without the use of food additives and preservatives.

FreshUs Oxygen Absorbent not only extends the shelf life of perishable food products, but helps to keep the quality of the product as well.

As shown in the table below, FreshUs Oxygen Absorbent is proven to have better performance in preserving perishable goods better than Gas

Flushing, and is much more efficient.

* Mold has been shown to growth in 20 days at 25 deg C at 0.2% residual oxygen (From "Techniques for the preservation of food

by employment of an oxygen absorber," Nakamura and Hoshino, 1983)

| Packaging Method | Results | Benefit |

|---|---|---|

| Gas Flushing | Approximately 0.5 to 5% Residual Oxygen | Provides Some Control of Aerobic Microbial Growth |

| Vacuum and Back Flush | Achieves as little as 0.1% Residual Oxygen | Controls Microbial Growth Temporarily* |

| FreshUs | Reduces and maintains oxygen content in packaging to below 0.01% | Eliminates Aerobic Microbial Growth and Oxidative Chemical Reactions in Packaging |

Oxygen, it's something that we cannot live without. Without oxygen, we wouldn't be able to breath,

function and basically live. It is a necessity that all life must have, but there are in our lives that we

can do without oxygen. Oxygen is known to cause food spoilage through oxidation or it supports other

organisms that ruin our food by being one of its basic necessities of life too.

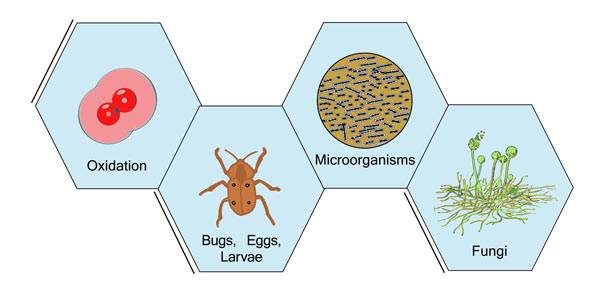

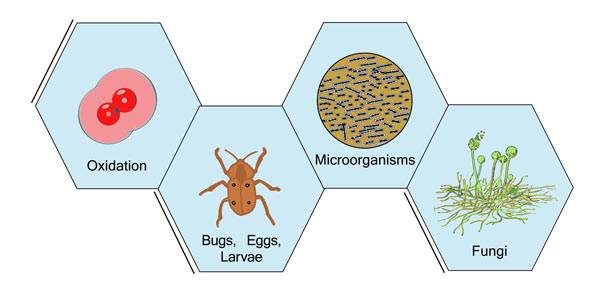

Oxidation is why iron rusts, newspaper yellows, and silver tarnishes. It also causes many nasty changes to food products that change flavor, texture, appearance and nutritional value.

Oxidation causes:

In addition to causing damage, oxygen also allows all sort of organisms to infest foods, sometimes causing great harm:

Oxygen is required for all these things to happen and that is why removing it can have a dramatic effect in food preservatives, and all this without any addition of harmful chemicals.

Oxidation is why iron rusts, newspaper yellows, and silver tarnishes. It also causes many nasty changes to food products that change flavor, texture, appearance and nutritional value.

Oxidation causes:

- Oils and fats to become rancid

- Darkening and browning

- Loss of nutrients

- Dulling of flavors in baked goods

In addition to causing damage, oxygen also allows all sort of organisms to infest foods, sometimes causing great harm:

- Oxidation promotes fungi, mold, & mildew

- Allows worms, bugs, eggs, and larvas to thrive

- And promotes growth of other microorganisms

Oxygen is required for all these things to happen and that is why removing it can have a dramatic effect in food preservatives, and all this without any addition of harmful chemicals.

CAUTION: Science and a little math ahead! Easy ”worry-free” information is available above

Oxygen Absorbing Packets (Oxygen Absorbers) are rated according to how much oxygen they will absorb, e.g., a 100cc Oxygen Absorbers will absorb 100cc's of oxygen. There are different types of oxygen absorbers. They contain an iron carbonate formulation, along with a tiny amount of entrapped water, and they chemically trap available oxygen from the environment. This process creates iron oxide, which is the same process that makes a nail rust. This reaction is exothermic, meaning that heat is released as the oxygen is absorbed, but not enough to be of concern during normal use and you likely will not even notice.

Oxygen absorbers are not air absorbers. Sometimes users expect to see a dramatic vacuum effect, but while it is true that you are likely to notice a volume decrease, oxygen is only 21% of air and the rest of the air will always remain, regardless of how many Oxygen Absorbers are used. The rest of the air is mostly nitrogen, with trace amounts of some other gases that are inconsequential to food storage.

Calculations For Oxygen Absorbers

First, we need to know the volume of the container we are going to deoxygenate in cc's. (cubic centimeters) Oxygen, as a gas, is measured in cc's, and containers are typically measured in milliliters, (ml) but conveniently, 1 ml = 1 cc.

Google is great for this: For example, if we have a pint jar, you can type in the search bar, “1 pint in mls” or “16oz in mls” and you will learn that a pint jar is roughly 473ml which is 473cc's. So, a pint jar holds 473 cc's of air.

Now we need to calculate how much oxygen is in the jar. (To make the calculations easier, we will use 20% or 1/5 as the oxygen content of air) Because oxygen is 20% or 1/5th or air, we can divide:

473cc/5 = 94.6 cc

So, an EMPTY pint jar contains 94.6 cc's of oxygen and will be deoxygenated by using an Oxygen Absorbers of 100cc's or larger. You can also fill that jar with product and still use a 100cc Oxygen Absorbers, OR you could account for the volume of the product and use a smaller Oxygen Absorbers...

To account for the product volume, you need to know how much air is in the product. Air is contained in the product in two ways: embedded air contained within the food particles and interstitial air in-between the food particles. There can be a surprising amount of air within the food itself and this air needs to be accounted for.

A lot of misinformation on the internet is related to people thinking items with small particles (like flour) are “dense” and therefore have less air volume, but particle size is actually not important. Believe it or not, a pool filled with marbles will have the same interstitial air volume as one filled with basketballs. Yes, the basketballs will have much larger pockets of air, but there are far fewer of them. Think of a checkerboard with just 2 large black squares and 2 large white squares... ½ of it's area is black and ½ white. What if it had 100 small black squares and 100 small white ones? 1000? Even with tiny squares it is still ½ black and ½ white as long as the squares are all a uniform size.

What does matter is particle size distribution, or in other words, whether you have particles that are all a uniform size or if you have a lot of particles of different sizes. If you have a pool filled with basketballs AND marbles, the marbles can fill in all the large pockets of air. So, products with uniform particle sizes will have more interstitial air than products with a greater distribution of particle sizes.

The other really important factor is degree of agglomeration, which just means how tightly everything is packed. Unsifted flour contains less air than sifted flour because it is more agglomerated. It is always best to pack food tightly to give it the smallest possible air volume.

How can you possibly know the particle size distribution and degree of agglomeration of your food products? There is a very simple test you can perform that will give you a very good idea of the air volume: If you take 2 cups of water and 1 cup of your product, then mix them really good and measure the result, you will end up with something less than 3 cups. The difference between 3 cups and the measured volume of your “product soup” is the amount of air that was in that cup of product. So,

Air volume of 1 cup of product = 3 cups – (volume of product soup in cups)

If your product soup measures 2 ½ cups, you know that ½ cup of the product was air, or it was 50% air by volume. If your product soup measures 2 ¼ cups, then ¾ cup of the product was air, or it was 75% air by volume.

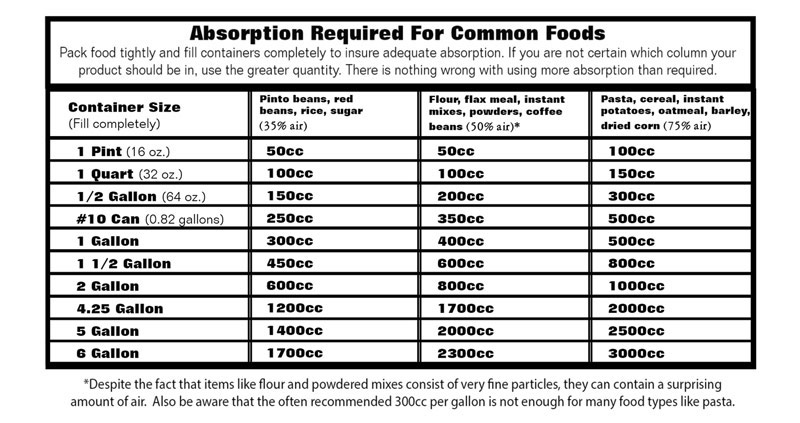

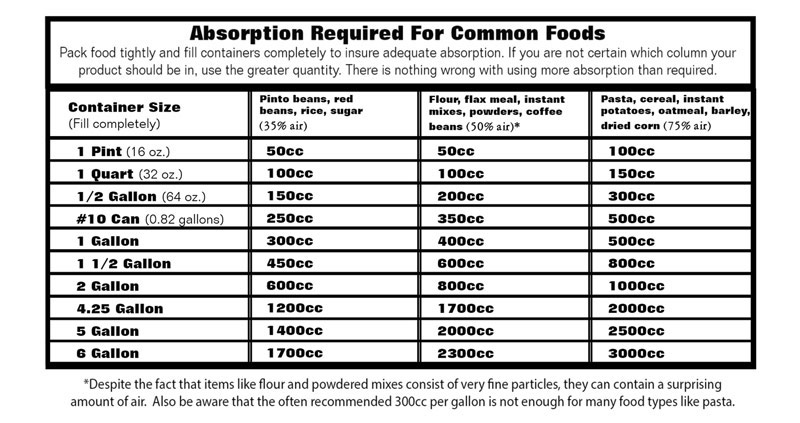

The following chart shows the air volumes of some popular LTFS products and the absorption required by container size:

Oxygen Absorbing Packets (Oxygen Absorbers) are rated according to how much oxygen they will absorb, e.g., a 100cc Oxygen Absorbers will absorb 100cc's of oxygen. There are different types of oxygen absorbers. They contain an iron carbonate formulation, along with a tiny amount of entrapped water, and they chemically trap available oxygen from the environment. This process creates iron oxide, which is the same process that makes a nail rust. This reaction is exothermic, meaning that heat is released as the oxygen is absorbed, but not enough to be of concern during normal use and you likely will not even notice.

Oxygen absorbers are not air absorbers. Sometimes users expect to see a dramatic vacuum effect, but while it is true that you are likely to notice a volume decrease, oxygen is only 21% of air and the rest of the air will always remain, regardless of how many Oxygen Absorbers are used. The rest of the air is mostly nitrogen, with trace amounts of some other gases that are inconsequential to food storage.

Calculations For Oxygen Absorbers

First, we need to know the volume of the container we are going to deoxygenate in cc's. (cubic centimeters) Oxygen, as a gas, is measured in cc's, and containers are typically measured in milliliters, (ml) but conveniently, 1 ml = 1 cc.

Google is great for this: For example, if we have a pint jar, you can type in the search bar, “1 pint in mls” or “16oz in mls” and you will learn that a pint jar is roughly 473ml which is 473cc's. So, a pint jar holds 473 cc's of air.

Now we need to calculate how much oxygen is in the jar. (To make the calculations easier, we will use 20% or 1/5 as the oxygen content of air) Because oxygen is 20% or 1/5th or air, we can divide:

473cc/5 = 94.6 cc

So, an EMPTY pint jar contains 94.6 cc's of oxygen and will be deoxygenated by using an Oxygen Absorbers of 100cc's or larger. You can also fill that jar with product and still use a 100cc Oxygen Absorbers, OR you could account for the volume of the product and use a smaller Oxygen Absorbers...

To account for the product volume, you need to know how much air is in the product. Air is contained in the product in two ways: embedded air contained within the food particles and interstitial air in-between the food particles. There can be a surprising amount of air within the food itself and this air needs to be accounted for.

A lot of misinformation on the internet is related to people thinking items with small particles (like flour) are “dense” and therefore have less air volume, but particle size is actually not important. Believe it or not, a pool filled with marbles will have the same interstitial air volume as one filled with basketballs. Yes, the basketballs will have much larger pockets of air, but there are far fewer of them. Think of a checkerboard with just 2 large black squares and 2 large white squares... ½ of it's area is black and ½ white. What if it had 100 small black squares and 100 small white ones? 1000? Even with tiny squares it is still ½ black and ½ white as long as the squares are all a uniform size.

What does matter is particle size distribution, or in other words, whether you have particles that are all a uniform size or if you have a lot of particles of different sizes. If you have a pool filled with basketballs AND marbles, the marbles can fill in all the large pockets of air. So, products with uniform particle sizes will have more interstitial air than products with a greater distribution of particle sizes.

The other really important factor is degree of agglomeration, which just means how tightly everything is packed. Unsifted flour contains less air than sifted flour because it is more agglomerated. It is always best to pack food tightly to give it the smallest possible air volume.

How can you possibly know the particle size distribution and degree of agglomeration of your food products? There is a very simple test you can perform that will give you a very good idea of the air volume: If you take 2 cups of water and 1 cup of your product, then mix them really good and measure the result, you will end up with something less than 3 cups. The difference between 3 cups and the measured volume of your “product soup” is the amount of air that was in that cup of product. So,

Air volume of 1 cup of product = 3 cups – (volume of product soup in cups)

If your product soup measures 2 ½ cups, you know that ½ cup of the product was air, or it was 50% air by volume. If your product soup measures 2 ¼ cups, then ¾ cup of the product was air, or it was 75% air by volume.

The following chart shows the air volumes of some popular LTFS products and the absorption required by container size:

When creating a long-term food storage plan, it is best to imagine using it. If tonight you needed to use your food supply

to feed your family, what would be easy to fix? What would they ask for? It wouldn't make much sense to fill 5 gallon buckets

with rice if your family hates rice, or save flour if you don't know what to do with it. There are plenty of great food

storage choices, so pick the ones that are best for you and your family. Remember to include spices and treats too.

Oxygen Absorbers must only be used with food that has a low moisture content. (under 15%) If a food product normally requires refrigeration after opening then that means it is susceptible to anaerobic bacteria, and needs to be canned or frozen to be stored long-term.

Here is a list of food products that are great for use with oxygen absorbers:

You can often keep products in their original packages, but if you do, poke a couple holes in the packages so that the oxygen will be removed. Most products are packaged using gas flushing to reduce oxygen levels, but Oxygen Absorbers do a much better job.

Coffee beans will give off a gas. They CAN be stored long-term but if you use a Mylar bag you may see it puff up a little over time.

Salt, sugar, honey and cornstarch do not spoil and do not need Oxygen Absorbers. You may choose to add a desiccant to buffer the moisture level but it is not necessary. Iodized salt may become yellow over time but the color change is safe and will not effect the quality otherwise.

Oxygen Absorbers must only be used with food that has a low moisture content. (under 15%) If a food product normally requires refrigeration after opening then that means it is susceptible to anaerobic bacteria, and needs to be canned or frozen to be stored long-term.

Here is a list of food products that are great for use with oxygen absorbers:

- Rice

- Beans

- Pasta

- Dehydrated fruit/veggies

- Potato flakes

- Nuts

- Trail mix

- Cereal

- Jerky

- Oatmeal

- Powdered milk, juice

- Pet food

- Seeds

- Crackers

- Wheat berries

- Flour

- Dried corn

- Flax

- Lentils

- Chick peas

- Corn meal

- Freeze-dried eggs

- Non dairy creamer

- Coconut

- Spices

- Herbs

- Chips

- Bread mixes*

- Cake mixes*

- Tortilla mix*

- Ramen noodles

- Dehydrated soups

- Bouillon cubes

- Medications

- Vitamins

You can often keep products in their original packages, but if you do, poke a couple holes in the packages so that the oxygen will be removed. Most products are packaged using gas flushing to reduce oxygen levels, but Oxygen Absorbers do a much better job.

Coffee beans will give off a gas. They CAN be stored long-term but if you use a Mylar bag you may see it puff up a little over time.

Salt, sugar, honey and cornstarch do not spoil and do not need Oxygen Absorbers. You may choose to add a desiccant to buffer the moisture level but it is not necessary. Iodized salt may become yellow over time but the color change is safe and will not effect the quality otherwise.

Freezer Burn Is A Problem We Are All Familiar With... But What Exactly Is It?

Over time, the texture of food stored in the freezer becomes dry, brittle, or leathery, vivid colors turn to shades of brown, and flavors become bland or downright detestable. There are two things going on that cause these changes to frozen food: Sublimation and oxidation.

Water can turn to vapor inside the freezer just as it does outside. Just as a puddle of water evaporates into water vapor, a similar process called sublimation will happen where frozen water will transition to vapor – completely skipping the liquid phase!

This water vapor transition occurs on the surface of the food stored in your freezer. Water molecules migrate to the surface where they either remain as a frosty covering on your food or they become water vapor that escapes into your freezer, traveling to the coldest areas such as the walls. Here, sublimation often creates a brilliant ice cave out of the water from your food leaving your food dry.

Oxygen is also very destructive. Oxidation is the process that turns a freshly cut apple brown and iron into rust. It is responsible for the stale taste in old food as well as loss of nutritive value and color changes. Fats within food oxidize and become rancid. Oxidation will occur even when sublimation does not, and will happen throughout your food, not just on the parts that dry out.

The longer something is in the freezer, the more it is subject to the processes that cause freezer burn.

What Can Be Done?

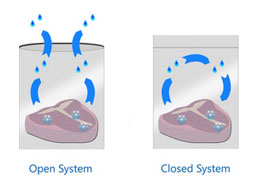

In order to keep water from leaving your food to travel around your freezer, you need to create a closed system – or at least get as close as possible – so that the water vapor leaving your food is equal to the water vapor absorbed by your food. Vacuum sealing is a pretty good choice. Freezer bags and carefully wrapping in plastic wrap will offer a fair amount of protection too, but none of the plastic products available at your local store will completely keep water vapor in, or keep oxygen out.

Preventing oxidation is even more difficult. (or at least it used to be) Oxygen is very sneaky and the only complete barriers to it are glass and metal. Plastics vary greatly in their Oxygen Transmission Rates, with plastic wrap being almost useless to HDPE or PETE plastic that can keep oxygen at bay for a few years if properly sealed.

How To Use Oxygen Absorbers For Cold Storage

FreshUsPac specializes in flexible barrier packaging and oxygen-free technology, bringing the protection of commercial product packaging to your home for the best protection available. With our products you can create a sealed environment with a water vapor equilibrium that inhibits sublimation and an oxygen-free atmosphere that prevents oxidation.

Oxygen absorbers are not a substitute for refrigeration or freezing. For long-term food storage they should either be used with dry, shelf-stable items (they should have a moisture content of less than 15%) or with frozen food. Food items that we are used to refrigerating are subject to aerobic bacteria, which are the only organisms that oxygen absorbers wont prevent.

Oxygen absorbers CAN be used in conjunction with refrigeration or freezing - with a few minor changes – and you can greatly improve the quality of your refrigerated or frozen food. They can prevent mold on cheese, keep bread items fresh, keep guacamole green, and save meat from freezer burn.

The things to keep in mind when using Oxygen Absorbers in cold storage are:

Temperature greatly effects the rate at which oxygen is absorbed. For every decrease of 15° F, it takes about twice as long for oxygen to be absorbed. Because it can take over 5 times longer to deoxidize a container in a freezer it may sometimes be appropriate to place it in the refrigerator for 24 to 48 hours before moving it to the freezer if it is safe to let it be at that temperature for that period.

Vacuum sealer bags are good to use if you will be using the product within a few months. Mylar is far superior for longevity, but quality vacuum sealer bags can keep an oxygen free environment for several months.

Do not use oxygen absorbers to extend storage time in the refrigerator. Also limit the amount of time food spends in the “Danger Zone” between 40° F and 140° F, always cook raw meat to an internal temperature of 165° F, and practice good hygiene and food safety guidelines.

Food packaging has taken a great leap forward in the past two decades with oxygen absorbers and barrier films such as the metalized Mylar®. This technology has the ability to maintain an oxygen-free atmosphere for decades, preventing oxidation and contamination from mold, bugs, and other oxygen-dependent organisms.

Over time, the texture of food stored in the freezer becomes dry, brittle, or leathery, vivid colors turn to shades of brown, and flavors become bland or downright detestable. There are two things going on that cause these changes to frozen food: Sublimation and oxidation.

Water can turn to vapor inside the freezer just as it does outside. Just as a puddle of water evaporates into water vapor, a similar process called sublimation will happen where frozen water will transition to vapor – completely skipping the liquid phase!

This water vapor transition occurs on the surface of the food stored in your freezer. Water molecules migrate to the surface where they either remain as a frosty covering on your food or they become water vapor that escapes into your freezer, traveling to the coldest areas such as the walls. Here, sublimation often creates a brilliant ice cave out of the water from your food leaving your food dry.

Oxygen is also very destructive. Oxidation is the process that turns a freshly cut apple brown and iron into rust. It is responsible for the stale taste in old food as well as loss of nutritive value and color changes. Fats within food oxidize and become rancid. Oxidation will occur even when sublimation does not, and will happen throughout your food, not just on the parts that dry out.

The longer something is in the freezer, the more it is subject to the processes that cause freezer burn.

What Can Be Done?

In order to keep water from leaving your food to travel around your freezer, you need to create a closed system – or at least get as close as possible – so that the water vapor leaving your food is equal to the water vapor absorbed by your food. Vacuum sealing is a pretty good choice. Freezer bags and carefully wrapping in plastic wrap will offer a fair amount of protection too, but none of the plastic products available at your local store will completely keep water vapor in, or keep oxygen out.

Preventing oxidation is even more difficult. (or at least it used to be) Oxygen is very sneaky and the only complete barriers to it are glass and metal. Plastics vary greatly in their Oxygen Transmission Rates, with plastic wrap being almost useless to HDPE or PETE plastic that can keep oxygen at bay for a few years if properly sealed.

How To Use Oxygen Absorbers For Cold Storage

FreshUsPac specializes in flexible barrier packaging and oxygen-free technology, bringing the protection of commercial product packaging to your home for the best protection available. With our products you can create a sealed environment with a water vapor equilibrium that inhibits sublimation and an oxygen-free atmosphere that prevents oxidation.

Oxygen absorbers are not a substitute for refrigeration or freezing. For long-term food storage they should either be used with dry, shelf-stable items (they should have a moisture content of less than 15%) or with frozen food. Food items that we are used to refrigerating are subject to aerobic bacteria, which are the only organisms that oxygen absorbers wont prevent.

Oxygen absorbers CAN be used in conjunction with refrigeration or freezing - with a few minor changes – and you can greatly improve the quality of your refrigerated or frozen food. They can prevent mold on cheese, keep bread items fresh, keep guacamole green, and save meat from freezer burn.

The things to keep in mind when using Oxygen Absorbers in cold storage are:

Temperature greatly effects the rate at which oxygen is absorbed. For every decrease of 15° F, it takes about twice as long for oxygen to be absorbed. Because it can take over 5 times longer to deoxidize a container in a freezer it may sometimes be appropriate to place it in the refrigerator for 24 to 48 hours before moving it to the freezer if it is safe to let it be at that temperature for that period.

Vacuum sealer bags are good to use if you will be using the product within a few months. Mylar is far superior for longevity, but quality vacuum sealer bags can keep an oxygen free environment for several months.

Do not use oxygen absorbers to extend storage time in the refrigerator. Also limit the amount of time food spends in the “Danger Zone” between 40° F and 140° F, always cook raw meat to an internal temperature of 165° F, and practice good hygiene and food safety guidelines.

Food packaging has taken a great leap forward in the past two decades with oxygen absorbers and barrier films such as the metalized Mylar®. This technology has the ability to maintain an oxygen-free atmosphere for decades, preventing oxidation and contamination from mold, bugs, and other oxygen-dependent organisms.

FreshUs offers various different sizes of oxygen absorbers (scavengers) ranging from 10cc to 2000cc. The size necessary

differs from the size of packaging being used to package products as well as the product itself, as the size of the

necessary Oxygen Absorbers is determined by the amount of oxygen that would be present inside the package.

In unsure of the size necessary for your packaging needs, please contact us at info@FreshUsPac.com with the following information and we will be able to assist you in determining the correct size of Oxygen Absorbent required to keep your products fresh.

Please provide the following information:

In unsure of the size necessary for your packaging needs, please contact us at info@FreshUsPac.com with the following information and we will be able to assist you in determining the correct size of Oxygen Absorbent required to keep your products fresh.

Please provide the following information:

- The type of food products being packaged

- They type of packaging material and type

- The full dimension of the packaging material when filled (Length X Width X Height)

- The total weight of the package when full

Yes, that is absolutely possible. It is hard to make the claim that food will be good for decades,

centuries even... but it is true. Everything that causes significant decay in shelf-stable food requires oxygen. The limiting

factor is how well you can keep the oxygen out.

We have Century Bags that, sealed properly with our Oxygen Absorbers, will literally keep oxygen away for 100 years or more. Our standard Mylar should be fine for well over 25 years when properly sealed with our oxygen absorbers. Food not subject to oxidation like honey has been found in Egyptian tombs in good shape. Without oxygen, there is no contamination from bugs, oxygen dependent organisms, mold, or oxidation. The products you refer to are using this exact same technology and you can easily do it at home.

We have Century Bags that, sealed properly with our Oxygen Absorbers, will literally keep oxygen away for 100 years or more. Our standard Mylar should be fine for well over 25 years when properly sealed with our oxygen absorbers. Food not subject to oxidation like honey has been found in Egyptian tombs in good shape. Without oxygen, there is no contamination from bugs, oxygen dependent organisms, mold, or oxidation. The products you refer to are using this exact same technology and you can easily do it at home.

You can put them in just about anything for extra protection. Mylar is extremely tough and

will probably be safe as is but you cant go wrong with putting them in a tub, 5 gallon bucket... You should try to

place everything 6 inches off the ground also.

Yes, mason jars kept in a dark place or properly sealed cans. Oxygen cannot go through glass

or metal. Mylar is virtually oxygen proof, but metal needs to be thicker than 15 microns to keep oxygen out completely.

Even though it can take decades for enough oxygen to get through Mylar, glass and thick metal can be even better barriers

and that is why they have been storage favorites too.

The Oxygen Absorbers need to be inside the heat-sealed bag. They are perfectly safe for contact

with food and need to be able to remove the oxygen surrounding the food. If you use a bucket, that is just extra protection

for the bag and you dont need to put an Oxygen Absorber in it. You dont even need a bucket for the process to work, but

it can protect the sealed bag from falling debris, animals, etc.

Yes, you are right, I think you just make a mess trying to jam them full. The real problem is

trying to seal them if they are too full and the seal is very important so you want to leave enough room to get a wide,

quality seal.

This happens quite frequently as our products are packaged with beef jerky products as well as pet treat products.

We would like to first inform you that our products are FDA Approved to be used with food products and will not cause any harm to your pet animal. We do ask that the owners watch over the pet animal for about 48 hours to see if it shows any symptoms of an allergic reaction. If the pet animal shows symptoms of having an allergic reaction, please take it to the vet immediately for treatment. If the pet animal is not showing any symptoms of an allergic reaction, we ask that the pet animal be given plenty of water to drink, as it will get thirsty.

In most cases the pet animal will not show any symptoms of an allergic reaction and will be completely fine.

We would like to first inform you that our products are FDA Approved to be used with food products and will not cause any harm to your pet animal. We do ask that the owners watch over the pet animal for about 48 hours to see if it shows any symptoms of an allergic reaction. If the pet animal shows symptoms of having an allergic reaction, please take it to the vet immediately for treatment. If the pet animal is not showing any symptoms of an allergic reaction, we ask that the pet animal be given plenty of water to drink, as it will get thirsty.

In most cases the pet animal will not show any symptoms of an allergic reaction and will be completely fine.

English

English